- Home

- Fire detection

- TFVSK1B

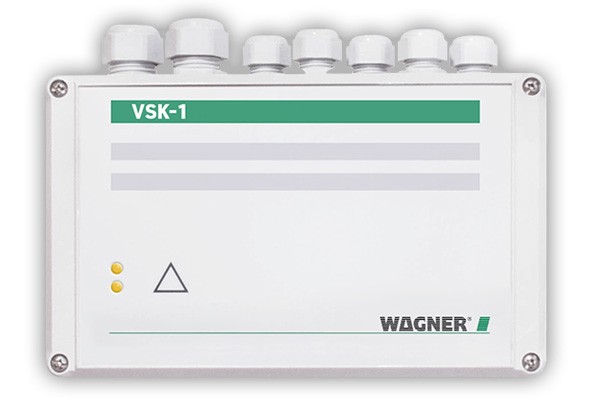

TFVSK1B

Automatic maintenance system with compressed air.

Automatic maintenance system with compressed air, for ASD aspirating pipes that operate in environments subject to low temperatures or in particularly dusty environments. The TFVSK1B control panel manages the operation of the blowing and shut-off valves, for the management of one or two independent aspirating pipes. Maintenance cycle activated by external control and/or programmed every 24 hours with simultaneous operation of the two pneumatic maintenance channels. The compressed air used must be clean, dry and free of oil. 24V DC supply voltage. Consumption at rest 20mA. Consumption during the maintenance cycle 100mA for each pneumatic maintenance channel. The set-up of the control panel must be completed with a TFMC-VC-x-x microprocessor, chosen according to the operating context and with the TFFW-VC label to be applied on the casing. The set-up of the pneumatic channel consists of: a TFSSK-MF quick release fitting, a TFAVK shut-off valve and a TFDVK blowing valve, the valves must be chosen according to the context of use. The pneumatic equipment must be doubled if the system manages the maintenance of two aspirating pipes. Operating temperature -40...+ 60°C. Polycarbonate casing. Dimensions (L x H x D) 200 x 140 x 80mm.

Code: TF10TFVSK1B